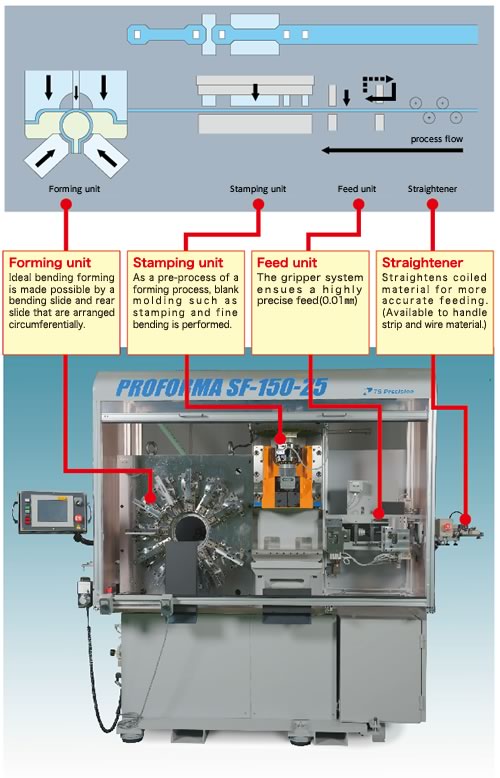

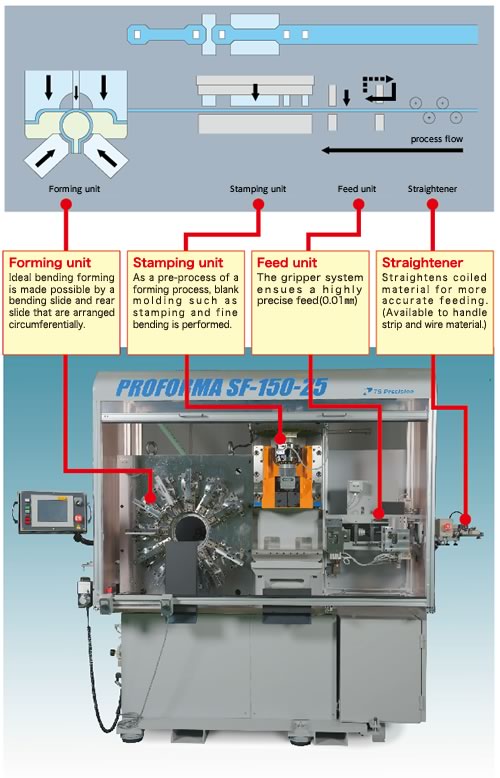

This is a deformation processing machine which is composed of a feeding device that transports materials from hoop materials to materials at a certain speed and a stamping device that crushes materials and does stamping.

This is a deformation processing machine which is composed of a feeding device that transports materials from hoop materials to materials at a certain speed and a stamping device that crushes materials and does stamping.